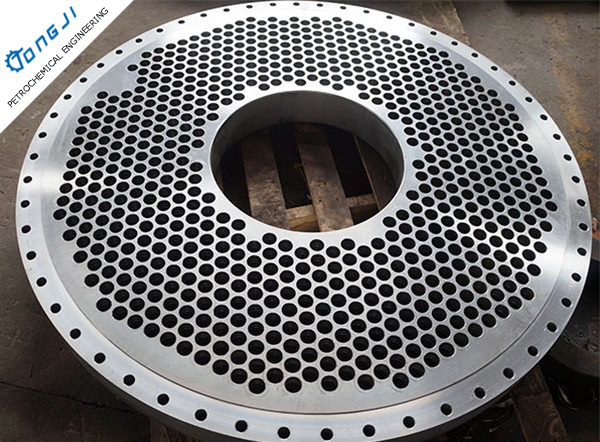

Titanium Tubings are suitable for environments and applications where the properties of stainless steels are not sufficient.

Specifications: ASTM B338, ASME SB338, ASTM B861, ASME SB861

ASTM B862, ASME SB862, NACE MRO 175-94

Grades: Gr1,Gr 2,Gr 7,Gr 9,Gr 11,Gr 12, Gr16,Gr 17 etc

Dimensions Range:

Seamless Type OD 2.0–219.1 mm , WT 0.3 to 24 mm, Length Max 18,000mm

Titanium tubes are delivered in straight lengths, or U-bent tubes, Coiled tubes.

Welded Type OD 19.05-1219 mm ,WT 0.5 to 12.7mm.also length and tolerance subject to the buyer's decisions.

BASIC TENSION DATA

| Grade | Tensile Strength,min | Yield Strmgh, 0.20% offset Yield | Elongation in 2 in. or 50mm, Min. % | ||||

| Ksi | Mpa | Min. | Max. | ||||

| Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 3 | 65 | 450 | 55 | 380 | 80 | 550 | 18 |

| 5 | 130 | 895 | 120 | 828 | ... | ... | 10 |

| 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 9A | 90 | 620 | 70 | 483 | ... | ... | 15C |

| 9B | 125 | 860 | 105 | 725 | ... | ... | 10 |

| 11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| 12 | 70 | 483 | 50 | 345 | ... | ... | 18C |

| 16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 17 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

A:Properties for colod-worked and stress-relieved

B:Annealed

C: Solution treated

Chemical Analysis

CP Titanium Grade 1

Ti Grade 1 is the softesr titanium with the highest ductility, good cold fromability which gives Ti Grade 1 an excellent resistance from mild to high oxidizaiton.

| Chemical composition (weight %) | ||||||||||||

| O | N | C | H | Fe | AL | V | Ni | Mo | Pd | Others | Residuals | Ti |

| 0.18 Max | 0.03 Max | 0.08 Max | 0.20 Max | 0.4 Max | Bal | |||||||

CP Titanium Grade 2

Ti Grade 2 has moderate strength with excellent cold formability, weldability. This titanium also has excellent resistance to high oxidization.

| Chemical Analysis of CP Titanium Grade 2 | ||||||||||||

| Chemical composition (weight %) | ||||||||||||

| O | N | C | H | Fe | AL | V | Ni | Mo | Pd | Others | Residuals | Ti |

| 0.25 Max | 0.03 Max | 0.08 Max | 0.015 Max | 0.30 Max | 0.4 Max | Bal | ||||||

Titanium Alloy Grade 5

Ti Grade 5 has very high strength but relatively low ductility. The main application of this alloy is in aricraft and spacecraft. Offshore use is growing. The alloy is weldable and can be precipitation hardened.

| Chemical Analysis of Titanium Alloy Grade 5 | ||||||||||||

| Chemical composition (weight %) | ||||||||||||

| O | N | C | H | Fe | AL | V | Ni | Mo | Pd | Others | Residuals | Ti |

| 0.20 Max | 0.05 Max | 0.08 Max | 0.015 Max | 0.40 Max | 5.5-6.75 | 3.5-4.5 | 0.4 Max | Bal | ||||

Titanium Grade 7

Ti Grade 7, Most corrosion-resistant titanium alloy offering outstanding resistance to general and localized crevice corrosion in a wide range of oxidizing and reducing acid environments including chlorides, with a good balance of moderate strength, reasonable ductility and excellent weldability. Physical and mechanical properties equivalent to Grade 2.

| Chemical Analysis of Titanium Grade 7 | ||||||||||||

| Chemical composition (weight %) | ||||||||||||

| O | N | C | H | Fe | AL | V | Ni | Mo | Pd | Others | Residuals | Ti |

| 0.25 Max | 0.03 Max | 0.08 Max | 0.015 Max | 0.30 Max | 0.12-0.25 | 0.4 Max | Bal | |||||

Titanium Grade 9

Ti Grade 9, is sometimes referred to as "half 6-4". It offers 20-50% higher strength than C.P. grades, but is more formable and weldable than Ti-6Al-4V.Grade 9 combines strength, weldability and formability. The alloy has excellent formability plus higher tensile strength than the strongest unalloyed grade.

| Chemical Analysis of Titanium Alloy Grade 9 | ||||||||||||

| Chemical composition (weight %) | ||||||||||||

| O | N | C | H | Fe | AL | V | Ni | Mo | Pd | Others | Residuals | Ti |

| 0.15 Max | 0.03 Max | 0.08 Max | 0.015 Max | 0.25 Max | 2.5-3.5 | 2.0-3.0 | 0.4 Max | Bal | ||||

Titanium Grade 11

Ti Grade 11, is the same as Grade 1, but with Pd for better corrosion resistance. Grade 11 has optimum ductility and cold formability. It has also useful strength, high-impact toughess and excellent weldability.

| Chemical Analysis of Titanium Grade 11 | ||||||||||||

| Chemical composition (weight %) | ||||||||||||

| O | N | C | H | Fe | AL | V | Ni | Mo | Pd | Others | Residuals | Ti |

| 0.18 Max | 0.03 Max | 0.08 Max | 0.015 Max | 0.20 Max | 0.12-0.25 | 0.4 Max | Bal | |||||

Titanium Grade 12

Ti Grade 12 is highly weldable, exhibiting improved strength allowable at increased teperatures, combined with superior crevice corrosion resistance, and excellent resistance under oxidizing to mildly reducing conditions, especially chlorides.

| Chemical Analysis of Titanium Grade 12 | ||||||||||||

| Chemical composition (weight %) | ||||||||||||

| O | N | C | H | Fe | AL | V | Ni | Mo | Pd | Others | Residuals | Ti |

| 0.25 Max | 0.03 Max | 0.08 Max | 0.015 Max | 0.30 Max | 0.6-0.9 | 0.2-0.4 | 0.12-0.25 | 0.4 Max | Bal | |||

Titanium Grade 16

Ti Grade 16 is corrorion-resistant material offering outstanding resistance to general and localized crevice corrosion in a wide range of oxidizing and reducing acid environments including chiorides. Has a good balance of moderate strength, reasonable ductility and excellent weldability.

| Chemical Analysis of Titanium Grade 16 | ||||||||||||

| Chemical composition (weight %) | ||||||||||||

| O | N | C | H | Fe | AL | V | Ni | Mo | Pd | Others | Residuals | Ti |

| 0.25 Max | 0.03 Max | 0.08 Max | 0.015 Max | 0.30 Max | 0.04-0.08 | 0.4 Max | Bal | |||||

Titanium Grade 17

Ti Grade 17, is the same as Grade 1, but with Pd for better corrosion resistance. Grade 17 has optimum ductility and cold formability with useful strength, high-impact toughness, and excellent weldability. Very resistant to crevice corrosion.

| Chemical Analysis of Titanium Grade 17 | ||||||||||||

| Chemical composition (weight %) | ||||||||||||

| O | N | C | H | Fe | AL | V | Ni | Mo | Pd | Others | Residuals | Ti |

| 0.18 Max | 0.03 Max | 0.08 Max | 0.015 Max | 0.20 Max | 0.04-0.08 | 0.4 Max | Bal | |||||