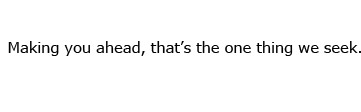

Studded Tubes are applied to convection chamber of heating furnace in petrochemical industry to increase the heat transfer coefficient at the fuming side. Studded Tubes are two or three times the square of light Tubes. Due to the usage of studded Tubes, the hot strength can be obtained as the same as radiation in the reasonable design. Studded Tubes manufactured by our company adopt resistance welding method. Welding process is controlled by PLC program. Feeding motor and graduation use servo motor. Studded number can be set via the human-computer interface. The graduation parameter and compensating coefficient can be set according to technical requirements to ensure the quality and precision of products.

Technical parameter of Studded Tube

| Technical Range | ||

| Tube OD(mm) | Tube Thickness(mm) | Tube Height(mm) |

| 60-219 | 4-20 | 10-38 |

| Material & Length Range | ||

| Tube | Stud | Tube Length(m) |

| A106GrB, A335 P5/P9 A204 TP304 | CS ANSI 410, SS304 5%Cr-1/2Mo | 1-15 |

Technical parameter of Studded Tube

| Technical Range | ||

| Tube OD(mm) | Tube Thickness(mm) | Tube Height(mm) |

| 60-219 | 4-20 | 10-38 |

| Material & Length Range | ||

| Tube | Stud | Tube Length(m) |

| A106GrB, A335 P5/P9 A204 TP304 | CS ANSI 410, SS304 5%Cr-1/2Mo | 1-15 |

Technical parameter of Studded Tube

| Technical Range | ||

| Tube OD(mm) | Tube Thickness(mm) | Tube Height(mm) |

| 60-219 | 4-20 | 10-38 |

| Material & Length Range | ||

| Tube | Stud | Tube Length(m) |

| A106GrB, A335 P5/P9 A204 TP304 | CS ANSI 410, SS304 5%Cr-1/2Mo | 1-15 |